Key Features

- High tech polyester covering

- Unique multi temperature-controlled adhesive shrinkage system

- Versatile and easy to apply

- Patented polymerizing process permanently fuses the color to the polyester film covering, eliminating the possibilities of color-layer separation and permits repositioning of the covering on your model.

- Light weight at .30 oz/sq. ft.

- Fuel proof to glow fuel, gas, and smoke oil. Water proof as well.

Overview

Hangar 9® UltraCote® is a high tech polyester covering that features a unique multi temperature-controlled adhesive and shrinkage system, making it versatile and easy to apply. A patented polymerizing process permanently fuses the color to the polyester film covering, eliminating the possibilities of color-layer separation and permits repositioning the covering on your model. UltraCote's unique ability to both shrink and stretch make it superior to other coverings for going around tight curves and wingtips.

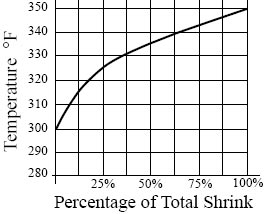

Temp ranges are as follows:

Adhesion to wood begins at 200 to 220 degrees F.

Shrinkage onset begins at 300 degrees F.

Maximum shrinkage is at 350 degrees F.

Detailed Information

|

|||

|---|---|---|---|

|

Surface Preparation: |

||

|

Pro Tip - Some professional builders “raise the grain” then sand a second time with 320 or 400 grit paper for the ultimate finish. After the model is sanded, use a damp cloth to wipe down the model. Some modelers prefer to use a fine-mist squirt bottle filled with water to dampen the surfaces to be covered. As the surface dries, imbedded wood fibers in the surface will “stand up.” When dry, sand the surfaces again using 320 or 400 grit paper. Raising the grain now and sanding it off will prevent the grain from raising later under the covering, creating a bumpy finish. Vacuum the model thoroughly and avoid touching the model with oily hands.Your model is now ready for covering! |

|||

|

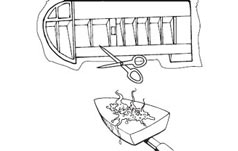

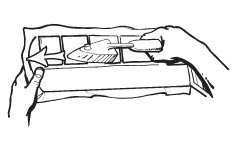

Trim Film to Size: |

||

|

Pro Tip - If the iron you're using does not display the actual temperature, here is a tip that will ensure your iron is properly set.Water boils at 212°F. Allow your iron to warm up at a medium setting. When the iron reaches its stabilized temperature, carefully pour a few drops of water on the iron's surface. Adjust the temperature until the water just begins to boil off. This method is surprisingly accurate and is generally within 10° (of the exact application temperature of 220). |

|||

|

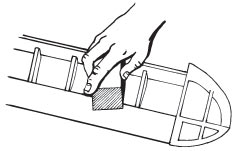

Tacking Covering to Spar: |

||

|

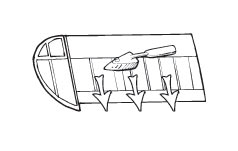

Covering a Solid-Sheeted Wing: |

||

|

Covering an Open-Structure Wing: |

||

|

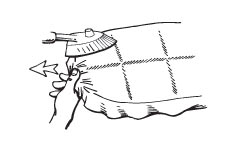

Sealing the Edges: |

||

|

Wing Tip: |

||

|

Pro Tip - If sealing the covering in tight areas such as corners or fillets, using the Hangar 9® ProTrim Sealing Tool is very helpful and results in a professional finish. |

|||

|

Covering the Top of the Wing: |

||

|

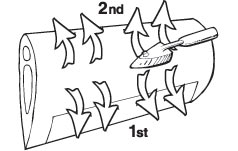

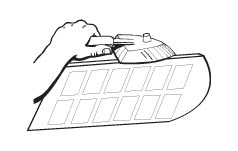

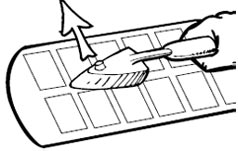

Shrinking the Covering: |

||

|

Pro Tip - Use heat, not pressure, to shrink the covering taught. If pressure is applied, gouges can be pressed into the wood. Let heat, not pressure, do the work. |

|||

|

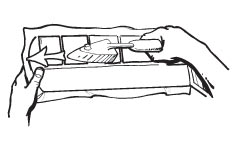

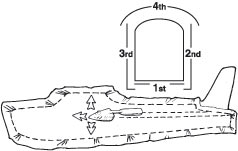

Covering Fuselages and Other Solid Surfaces: |

||

| Important: Even if you're experienced in applying other brands of covering, it’s important to read the following instructions. UltraCote® incorporates a unique multi temperature controlled adhesive and shrinkage system that makes achieving professional covering results easy. | |||

|

Multi-Temperature Control System:

|

|||

|

|||

|

|||

|

|||

| Important:Once UltraCote® is shrunk to a specific temperature, a higher temperature must be used to further shrink the covering. For example, if the covering was shrunk using 320°F and wrinkles begin to appear/reappear, it will be necessary to use over 320°F to achieve further shrinkage. | |||

|

Pro Tip - Always use the minimum heat necessary to remove wrinkles when tightening the covering, thus allowing plenty of shrinkage/temperature range remaining if it's necessary to further shrink the covering. |

|||

|

|

|||

|

Helpful Hints

|

|||

|

Multiple Colors: |

|||

|

|||